Features & Benefits

- Flow Range: Customer Specified Up to 6000 SCCM

- Linearity Error: 0.5 – 1.0% FS

- Repeatability: ± 0.15% FS

- Response Time: 40 msec

PRODUCT SPECIFICATIONS (Standard)

NOTE: Ask Us About Specification Enhancement

| Performance | |

|---|---|

| Flow Ranges | Any Customer Specified Flow Range Up to 6000 SCCM |

| Linearity | ± 0.5 - 1.0% of Full Scale (Typical) |

| Repeatability & Hysteresis | ± 0.15% FS |

| Response Time | 40 msec (Typical, from 2%-100 FS) |

| Temperature Coefficient | 0.09% / ºC from 20ºC Ambient Cal Temp |

| Fluid Requirements: | |

| Calibration Gas | Any, Non-Corrosive, Customer Specified |

| Pressure Range | Up To 100 psiA, Cal Pressure: 40 psiA (Typical) |

| Internal Leakage | 10-5 @ 1, 30 and 100 psi (He) |

| External Leakage | 2 x 10-6 sccm (He) |

| Electrical Requirements: | |

| Input Voltage (single supply) | 12V (+10% - 3%), 15V (+/- 10%), 24V (+/-10%) |

| Power Consumption | 3.0 Watts Maximum |

| Control & Output Voltage/Signal | 0-5 VDC, 0-10VDC, 1-5 VDC, 4-20mA, RS232 (Addressable) |

| Environmental Requirements: | |

| Operating Ambient Temp. | 0-50ºC |

| Storage Temperature | -40 to 70ºC |

| Humidity Range | 5% - 95% (Relative, non-condensing) |

| Nominal Temperature | 20ºC ± 5ºC |

| Mechanical Configuration: | |

| Input/Output Ports | Manifold Mount - Standard Footprint |

| Dimensions | L: 4.13” W: 1.00” H: 4.13” |

| Weight | 8.1 oz |

| Construction (wetted materials): | |

| Manifold | Nickel Plated Aluminum |

| O-Rings | Fluorocarbon (Viton®), others at additional cost |

| Valve Components | Brass 360, AISI 300 series, 430 FR Stainless Steel |

| Flow Sensor | Ceramic Flow Tube (non-out gassing), Silicon, Silicon Nitrite Gold, Aluminum Oxide Epoxy Sealant, Fluorocarbon (Viton®), Polythermide (100, 200 & 300 sccm MFC only) |

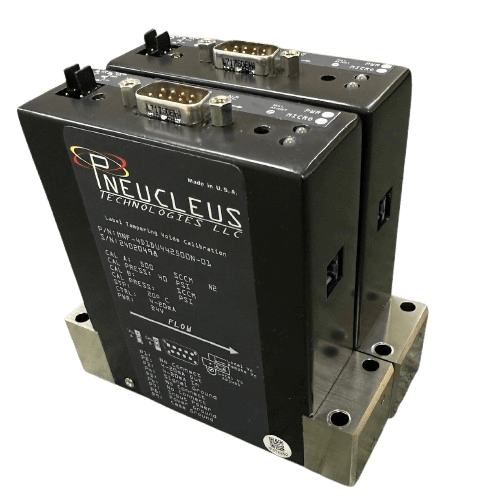

Pneucleus Technologies offers Maniflo Mass Flow Controllers (MFCs) that are manifold mount devices designed to regulate the flow of gases in various industrial applications. These controllers are known for their exceptional accuracy, stability, and flexibility in managing mass flow rates. The manifold mount mass flow controller, specifically, integrates seamlessly into manifold systems to optimize gas delivery with minimal space requirements. With features such as custom flow range MFC, outstanding repeatability, and fast response times, they offer high precision for a range of processes. Their adaptability ensures reliable performance in critical applications, enabling industries to maintain consistent gas flows with accuracy.

Key Features and Benefits

ManiFlo Mass Flow Controllers provide precise gas flow regulation, with custom flow ranges for versatility, ensuring reliable performance across demanding industrial applications. Below are some key features and benefits that make them stand out.

- Flow Range: The customizable flow range of the Maniflo Mass Flow Controller ensures it can meet a wide array of application requirements, accommodating flow rates ranging from very low to as high as 6000 SCCM. This adaptability makes it suitable for industries that demand flexibility in gas flow control. Whether for small-scale lab applications or large industrial systems, the controller can be tailored to provide precise control across various settings.

- Linearity Error: With a low linearity error range of 0.5 to 1.0% FS, the ManiFlo Mass Flow Controller ensures highly accurate gas flow measurements. This precision is crucial for applications where even slight deviations can lead to significant process disruptions or reduced efficiency. By minimizing measurement errors, it guarantees that the gas flow remains stable and consistent, ensuring optimal process performance.

- Repeatability: The ManiFlo Mass Flow Controller features exceptional repeatability with an accuracy of ±0.15% FS, which is crucial for maintaining consistent gas flow control. This high repeatability ensures that the system consistently delivers the same flow rate under the same conditions, thereby reducing potential process variations. As a result, industries can rely on its performance for critical applications that demand stable, repeatable flow over long periods.

- Response Time: The ManiFlo Mass Flow Controllers fast response time of just 40 milliseconds enables it to quickly adjust to changes in flow conditions, making it ideal for dynamic systems that require rapid corrections. This rapid reaction prevents any disruptions in the system, ensuring that the gas flow remains within the desired parameters. The short response time is especially beneficial in applications where process stability is crucial, such as in semiconductor manufacturing or lab experiments.

Customization Options: Customers can specify custom flow ranges tailored to their specific process requirements. A variety of output signal options are available to ensure compatibility with control systems. Different O-ring materials can be selected to ensure compatibility with various gases and operating conditions. Users can also tailor valve configurations to optimize gas flow control for their specific process needs. Additionally, the ability to calibrate with specific gases ensures accurate performance across diverse applications.

Industry-Wide Applications and Use Cases

Manifold mount mass flow controllers are ideal for industries that require precise control of gas flows. They offer high performance, reliability, and flexibility in applications across various sectors. Below are the industries that benefit from the use of these mass flow controllers:

- Gas Mixing Systems: The precise control of multiple gases in mixing systems ensures the correct proportions and flow rates are maintained, resulting in consistent product quality and improved process efficiency.

- Analytical Instrumentation: Accurate mass flow control is vital for analytical instrumentation. Manifold mount mass flow controllers facilitate precise gas delivery, ensuring high-accuracy measurements in analytical processes.

- OEM Gas Control Modules: Original Equipment Manufacturers (OEMs) rely on ManiFlo MFCs for integrating precise gas flow control into their custom systems. The compact design and high performance of these controllers make them an ideal choice for OEM applications.

- Semiconductor and Biotech: In semiconductor manufacturing and biotech applications, precise gas flow control is crucial for achieving high yield and maintaining process consistency. ManiFlo Mass Flow Controllers ensure the reliable delivery of gases used in these sensitive processes.

- Lab Automation and R&D: In laboratory automation and research, accurate mass flow regulation is essential for experiments and processes that demand high precision. These controllers provide the necessary control and stability for scientific research and testing.

Ready to optimize your gas flow management? The ManiFlo mass flow controller ensures precision in even in the most demanding environments. Contact Pnucleus Technologies today to learn more about how ManiFlo mass flow controllers can improve your gas flow control and enhance operational efficiency. Get started on optimizing your system with our expert solutions now!

FAQs

What types of gases can the custom flow range MFC handle?

The custom flow range MFCs are designed to handle any non-corrosive gas specified by the customer. This versatility makes them suitable for a wide range of applications, including analytical instrumentation and vacuum coating. However, they are not intended for use with corrosive gases, which would require different materials and design considerations.

What are the electrical requirements for the ManiFlo MFCs?

The ManiFlo MFCs operate with input voltages of 12V (+10% -3%), 15V (±10%), or 24V (±10%). They consume a maximum of 3.0 watts of power. Control and output signals are available in various formats, including 0-5 VDC, 0-10 VDC, 1-5 VDC, 4-20mA, and RS232 (addressable). This range of options enables integration with diverse control systems.

What is the operating temperature range of the ManiFlo MFCs?

The ManiFlo MFCs are designed to operate within an ambient temperature range of 0°C to 50°C. For storage, the temperature range extends from -40°C to 70°C. These specifications ensure that the controllers can function effectively in various environmental conditions, maintaining performance and reliability.

What is the internal and external leakage specification of the Manifold Mount Mass Flow Controller?

The Manifold Mount Mass Flow Controller has an internal leakage rate of 10^-5 sccm at 1, 30, and 100 psi (He), ensuring minimal gas loss and maintaining system integrity. The external leakage rate is 2 x 10^-6 sccm (He), which is critical for applications requiring high precision and low contamination levels. These low leakage rates are essential for maintaining the accuracy and reliability of the flow control system.

Can the ManiFlo MFCs be customized for specific applications?

Yes, the ManiFlo MFCs offer low-cost or no-cost customization options. Pneucleus Technologies encourages customers to request features and performance enhancements beyond the standard offerings. This flexibility enables the tailoring of the MFCs to meet the specific needs of various applications, ensuring optimal performance and customer satisfaction.