Precision Gas Flow Control at a Fraction of the Cost

Thermal Mass Flow Controllers with Direct-Sensing Technology

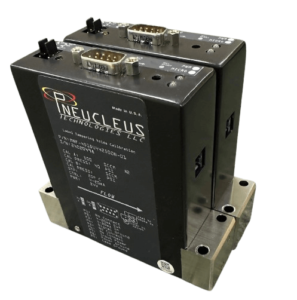

Pneucleus mass flow controllers are engineered with advanced direct-sensing thermal technology to deliver laboratory-grade precision in real-world industrial environments. With response times as fast as 40 ms, ±0.5% accuracy, and a 10,000:1 turndown ratio, they outperform traditional bypass designs by offering faster response, long-term stability, and reliable setpoint control.

Unlike conventional mass flow controllers that rely on complex bypass flow paths, Pneucleus controllers measure gas flow directly in the stream. This streamlined approach eliminates clogging risks, reduces maintenance, and lowers overall system cost – making high-performance gas flow control accessible for both laboratory and production applications.

| Precision Models | ||||

| Flow Range* | Up to 2000 sccm | Up to 20 SLPM | Up to 20 SLPM | |

| Linearity Error:** | ±0.5 – 1.0% FS | ±0.5 – 1.0% FS | 0.5 – 1.0% FS | |

| Repeatability | 0.15% FS | 0.15% FS | 0.15% FS | |

| Response Time | 40 msec | 150 msec | 150 msec | |

| OEM (Economical) Models | ||||

| Flow Range* | Up to 500sccm | Up to 20 SLPM | Up to 20 SLPM | |

| Linearity Error: | 1.0 – 3.0% FS | 1.0 – 3.0% FS | 1.0 – 3.0% FS | |

| Repeatability | 0.15% FS | 0.15% FS | 0.15% FS | |

| Response Time | 40 msec | 150 msec | 150 msec | |

* Customer-Specified

** Customer-Specified with Cost Impact

What Is a Mass Flow Controller?

A mass flow controller (MFC) is a precision instrument that actively measures and regulates the mass flow rate of gas in real time. Unlike mass flow meters (which only measure) or volumetric controllers (which fluctuate with pressure and temperature), MFCs use a closed-loop PID feedback system to maintain your exact setpoint. This stability is essential in semiconductor, analytical, and industrial applications where accuracy directly impacts yield, quality, and repeatability.

How Pneucleus Mass Flow Controllers Work

Every Pneucleus mass flow controller integrates three core components to achieve unmatched performance:

- InSitu-Sense™ Thermal Sensor – A microchip-sized sensor placed directly in the gas stream, delivering millisecond response without bypass delays.

- Tri-Planar™ Proportional Valve – A high-spring-rate valve with a 10,000:1 turndown ratio, vibration resistance, and thermal compensation for drift-free control.

- PID Feedback Controller – Continuously adjusts valve position to hold the setpoint steady, even under system fluctuations in pressure or temperature.

Result: Instant response, zero drift, and long-term stability across a wide range of operating conditions.

The Pneucleus Advantage: Why Direct Sensing Wins

Traditional mass flow controllers rely on a bypass design, splitting gas flow between a narrow sensing tube and the main channel, making them slower, more expensive, and prone to clogging. Pneucleus controllers eliminates the bypass entirely by measuring flow directly in the gas stream.

| Feature | Bypass (Traditional) | Direct Sensing (Pneucleus) |

| Response Time | 100–200 ms | As fast as 40 ms |

| Clogging Risk | High (narrow tubes) | Minimal (self-cleaning) |

| Maintenance | Frequent | Minimal |

| Total Cost of Ownership | Higher | Reduced |

Technology Highlights

InSitu-Sense™ Technology

- Ultra-low thermal mass → millisecond response

- Thermophoretic effect repels particles → prevents clogging

- 5 mm RTD spacing → eliminates temperature gradient errors

- Long-term stability → <0.2% FS drift over 7,500+ hours

Tri-Planar™ Valve Technology

- 110 lb/in spring rate → exceptional linearity

- 10,000:1 turndown → control from 0.01% to 100% FS

- Thermal compensation → zero parasitic drift

- <10⁻⁵ SCCM leakage (He) → superior shutoff and sealing

Pneucleus Mass Flow Controllers

| Model | Max Flow | Response | Size | Ideal Use Case |

| MicroFlo | 5000 SCCM | 40 ms | 2.0″ × 1.5″ × 1.85″ | Portable / OEM |

| MediFlo | 20,000 SCCM | 40–100 ms | 2.8″ × 1.5″ × 5.5″ | Industrial / Fab |

| MetaFlo | 20 SLPM | 150 ms | Low-profile | High-flow apps |

Applications of Pneucleus Mass Flow Controllers

1. Analytical Instrumentation

GC | GC-MS | ICP-MS | ICP-OES | FID | FPD

Eliminate baseline drift and ensure consistent retention times.

Typical setup: MicroFlo controlling He/H₂ carrier gas (25–100 SCCM).

2. Semiconductor Manufacturing

CVD | ALD | Plasma Etch | Sputtering | PVD

Fast response stabilizes flow during plasma ignition and process transitions.

Common config: MediFlo precision controller for process gases (500–5000 SCCM).

3. Vacuum Coating & Thin-Film

Optical coatings, solar cells, decorative coatings.

Low-drift performance prevents thickness variations and ensures consistent film quality.

4. Laboratory & Research

Elemental analysis, gas calibration, purging, environmental monitoring.

Economy models suit non-critical work; precision models provide reference-grade performance.

5. Industrial Automation

Process control, gas blending, combustion air, N₂ purging.

Analog and RS-232 outputs integrate easily with PLCs and SCADA systems.

3 Questions to Find Your Perfect Mass Flow Controller

1. What flow range do you need?

Sizing guideline: Select full-scale 1.5–2× your maximum expected flow for optimal accuracy and turndown.

- Up to 5000 SCCM → MicroFlo (compact, portable)

- 500–20,000 SCCM → MediFlo (versatile workhorse)

- >5 SLPM → MetaFlo (high-flow applications)

2. What accuracy do you require?

- Critical processes (semiconductor fab, calibration standards, research) → Precision models (±0.5–1.0% FS)

- General industrial (purging, blending, environmental) → Economy models (±3.0% FS)

3. What interface and control do you need?

- Simple systems → Analog (0-5V, 4-20mA) with local setpoint adjustment

- Networked/automated systems → RS-232 digital with addressable communication

- Dual gas capability → Dual-Cal option for two pre-programmed gas calibrations

Still unsure? Talk to an application engineer

Why Choose Pneucleus?

Engineered by experts, priced for reality. Pneucleus was founded by engineers who understood that exceptional performance shouldn’t require exceptional budgets. By eliminating the costly bypass design and focusing on what matters- accuracy, speed, and reliability- we deliver mass flow controllers that match or exceed the performance of legacy brands at a fraction of the cost.

Custom solutions welcome. Need a special flow range, gas calibration, or interface? We specialize in tailored solutions for OEM integrators and process engineers. Contact our application engineering team to discuss your requirements.

Frequently Asked Questions

What’s the difference between a mass flow meter and a mass flow controller?

Mass flow meters measure only. They provide a signal proportional to flow rate but have no control capability.

Mass flow controllers measure AND control via an integrated proportional valve and PID feedback loop. The controller continuously adjusts the valve position to maintain your setpoint, compensating for upstream pressure fluctuations and downstream process changes.

Bottom line: If you need stable, repeatable flow regardless of system conditions, you need a controller, not just a meter.

Can one controller handle multiple gases?

Yes. Our Dual-Cal feature stores two gas calibrations in memory, switchable via:

- Jumper selection (analog models) – physical switch for gas A or B

- Software command (digital RS-232 models) – remote switching without hardware access

Need more than 2 gases? We offer custom multi-gas calibrations with extended gas libraries. Contact engineering to discuss your gas matrix.

Common dual-gas setups:

- N₂ / Ar (semiconductor process)

- He / H₂ (GC carrier gas backup)

- Air / O₂ (combustion optimization)

Do you support corrosive gases?

Standard models are designed for non-corrosive gases including:

- Noble gases (Ar, He, Ne, Xe)

- N₂, O₂, Air, H₂

- Hydrocarbons (CH₄, C₃H₈)

- CO₂, CO

For corrosive or reactive gases (Cl₂, HCl, NH₃, SiH₄, etc.), consult our engineering team for:

- Material compatibility analysis

- Special wetted materials (Hastelloy, PCTFE, PTFE)

- Corrosion-resistant configurations

- Extended warranty options

Not sure if your gas is compatible? Send us your gas list and operating conditions – we’ll provide a compatibility assessment within 24 hours.