- devpneucleus

- Oct 13, 2025

- Blog

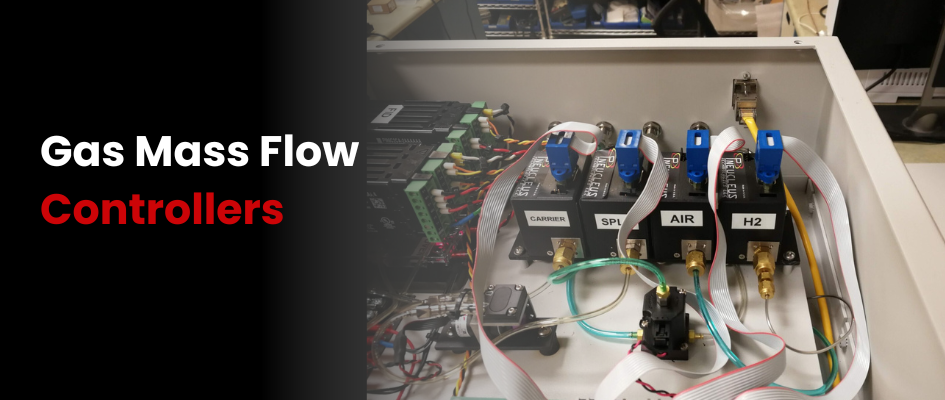

In modern industrial and scientific systems, precise gas flow control is essential for maintaining product quality, process stability, and operational efficiency. Applications ranging from analytical instrumentation to semiconductor manufacturing and vacuum coating systems demand instruments that can deliver accurate, repeatable gas flows under dynamic operating conditions. Among the technologies that meet these requirements, Gas Mass Flow Controllers (MFCs) have become critical tools for process engineers and researchers.

Advances in direct-sensing technology, combined with optimized proportional valve designs, have redefined the performance standards of MFCs, offering faster response times, improved stability, and reduced maintenance compared to traditional thermal and bypass designs.

Understanding Gas Mass Flow Controller?

A Gas Mass Flow Controller (MFC) is a precision device that measures and regulates the mass flow rate of gases in real time. Unlike a mass flow meter (MFM), which only measures flow, an MFC actively controls it using a closed-loop system consisting of:

- Flow Sensor – Detects the actual gas mass flow, commonly thermal-based.

- Control Valve – Modulates the gas flow to maintain the desired setpoint.

- PID Controller – Continuously compares measured flow with the target and adjusts the valve to achieve precise control.

This combination ensures consistent, repeatable gas delivery, which is vital for high-precision processes such as chemical vapor deposition (CVD), plasma etching, gas chromatography, and analytical instrumentation.

Mass Flow Controller vs. Mass Flow Meter

| Feature | Mass Flow Meter (MFM) | Mass Flow Controller (MFC) |

| Function | Measures only | Measures and actively controls |

| Components | Sensor + electronics | Sensor + valve + PID control |

| Output | Flow reading | Flow reading + regulated flow |

| Application | Monitoring, data logging | Active process control |

| Cost | Lower | Higher (includes control valve) |

MFCs are recommended wherever stable, repeatable gas flow is critical to process performance and product consistency.

Principles of Gas Mass Flow Measurement

Gas mass flow measurement relies on the thermal properties of the gas and its interaction with the sensor. The three main architectures are:

Thermal (Inline) Measurement

- Sensor heated to a constant temperature transfers heat to passing gas.

- Heat loss correlates with mass flow rate.

- Pros: True mass measurement, simple design.

- Limitations: Moderate response time (100–300 ms) and drift due to thermal gradients.

- Ideal for stable analytical systems and general process control.

Bypass Measurement

- Divides flow between a main laminar flow element and a small sensor channel.

- Pros: High linearity and calibration repeatability.

- Limitations: Slower response (150–300 ms), higher pressure drop, prone to clogging.

- Ideal for high-precision processes like semiconductor CVD and ALD.

Direct-Sensing Measurement

- Sensor placed directly in the main gas stream, eliminating bypass channels.

- Features microscale thermal transducers for rapid detection and minimal thermal inertia.

- Advantages:

- Extremely fast response (40–80 ms).

- High repeatability and low long-term drift (<0.1% FS per year).

- Minimal pressure drop (0.1–0.5 bar).

- Low maintenance and compact form factor.

- Best suited for dynamic applications, analytical instruments, OEM integration, and research setups.

Key Performance Comparison

| Parameter | Thermal (Inline) | Bypass | Direct-Sensing + Advanced Valve |

| Response Time (ms) | 100–300 | 150–300 | 40–80 |

| Accuracy (% FS) | ±1.0–1.5 | ±0.5–1.0 | ±0.5 |

| Repeatability (% FS) | ±0.2 | ±0.1 | ±0.1 |

| Long-Term Drift (%/yr) | 0.2–0.5 | 0.1–0.2 | <0.1 |

| Pressure Drop (bar) | 0.5–1.0 | 1–2 | 0.1–0.5 |

| Maintenance | Low | Moderate | Very Low |

| Complexity | Moderate | High | Low |

This comparison highlights how direct-sensing MFCs, especially when paired with high-precision valves, offer superior dynamic response, stability, and ease of integration.

Valve Design and Control Loop

The control valve is as critical as the sensor in determining an MFC’s dynamic performance. Traditional solenoid or piezoelectric valves require higher differential pressure and can introduce mechanical noise.

Modern designs, such as the Tri-Planar™ proportional valve, deliver:

- Multi-orifice plunger system for smooth, linear flow modulation.

- Minimal hysteresis (<0.05%).

- Low differential pressure operation (0.1–0.3 bar).

- Thermal compensation to eliminate drift over a wide temperature range.

When combined with direct-sensing technology, this valve achieves fast closed-loop response, minimal overshoot, and highly stable flow control.

Applications of Gas Mass Flow Controllers

Analytical Instrumentation: Gas chromatography, mass spectrometry, and ICP-MS rely on stable and repeatable gas flow. Direct-sensing MFCs provide fast stabilization for precise sampling and consistent results.

Semiconductor Manufacturing: Direct-sensing MFCs excel in rapid recipe transitions, plasma ignition, and gas switching in processes like CVD, ALD, and plasma etching.

Vacuum Coating & Thin Films: Sputtering and PVD systems benefit from low pressure drop and precise flow control to ensure uniform film deposition.

Research & OEM Systems: Fast-response, compact MFCs support flexible experimental setups, pilot-scale systems, and multi-channel integration.

Choosing the Right Gas Mass Flow Controllers for Your Application

Selecting the ideal Gas Mass Flow Controller is crucial for achieving optimal performance, efficiency, and reliability in your process. The right MFC ensures precise gas delivery, reduces operational costs, and minimizes downtime due to recalibration or maintenance. When choosing a controller, consider the following factors:

- Process Requirements: Identify the type of gas (non-corrosive vs. corrosive), maximum and typical flow rates, and required accuracy and response time. Understanding these parameters ensures the controller can handle the demands of your application without compromising performance.

- Pressure and Temperature Conditions: Ensure the available differential pressure meets the valve’s operational range. Operating within the recommended temperature limits (typically 0–50 °C for most MFCs) helps maintain accuracy and stability over time.

- Sensor Architecture: Compare thermal, bypass, and direct-sensing designs. Choose direct-sensing MFCs for fast response and dynamic control, bypass types for corrosive gases or ultra-linear requirements, and thermal inline MFCs for simple, stable processes.

- Valve Performance and Control: Evaluate valve characteristics such as hysteresis, control resolution, and minimum differential pressure. High-precision proportional valves, like the Tri-Planar™ design, paired with direct-sensing technology, offer superior loop response, flow stability, and reduced overshoot.

Material Compatibility: Confirm that the MFC materials are compatible with your process gases. Standard options include Ni-plated aluminum with Viton® seals, while high-performance applications may require ceramic flow tubes or all-metal seals for ultra-high vacuum systems.