Precision Gas Flow Measurement for Compact and Integrated Systems

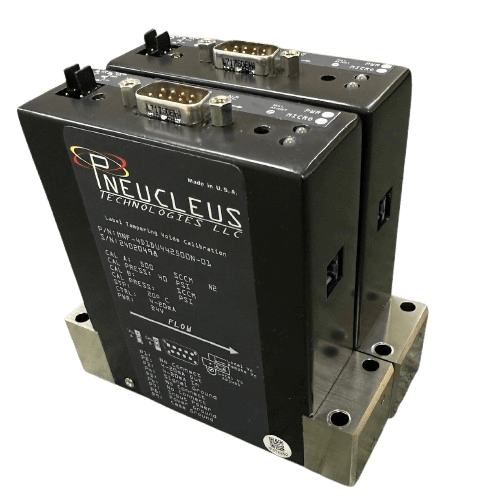

In industries where exact gas flow control is essential, even minor deviations can compromise process quality, safety, and efficiency. The ManiMeter™ Mass Flow Meter is designed for manifold mount systems, providing high accuracy, repeatability, and digital connectivity in a compact form factor.

Whether used in analytical research, semiconductor manufacturing, vacuum processes, or industrial automation, the ManiMeter ensures that gas flow is measured and delivered with precision, enabling engineers to maintain control over critical processes.

Features & Benefits

- Flow Range: Customer specified Up to 6000 SCCM

- Linearity Error: 0.5% FS

- Repeatability: 0.15% FS

- Response Time: 20 ms

PRODUCT SPECIFICATIONS (Standard)

NOTE: Ask Us About Specification Enhancement

| Performance | |

|---|---|

| Flow Ranges | Any Customer Specified Flow Range Up to 6000 SCCM |

| Linearity | ± 0.5 - 1.0% of Full Scale (Typical) |

| Repeatability & Hysteresis | ± 0.15% FS |

| Response Time | 20 msec (Typical, from 0%-100 FS) |

| Temperature Coefficient | 0.09% / ºC from 20ºC Ambient Cal Temp |

| Fluid Requirements: | |

| Calibration Gas | Any, Non-Corrosive, Customer Specified |

| Pressure Range | Up To 100 psiA, Cal Pressure: 14.7 psiA (Typical) |

| Internal Leakage | 10-5 @ 1, 30 and 100 psi (He) |

| External Leakage | 2 x 10-6 sccm (He) |

| Electrical Requirements: | |

| Input Voltage (single supply) | 12V (+10% - 3%), 15V (+/- 10%), 24V (+/-10%) |

| Power Consumption | 0.75 Watts Maximum |

| Output Voltage/Signal | 0-5 VDC, 0-10VDC, 1-5 VDC, 4-20mA, RS232 (Addressable) |

| Environmental Requirements: | |

| Operating Ambient Temp. | 0-50ºC |

| Storage Temperature | -40 to 70ºC |

| Humidity Range | 5% - 95% (Relative, non-condensing) |

| Nominal Temperature | 20ºC ± 5ºC |

| Mechanical Configuration: | |

| Input/Output Ports | Manifold Mount - Standard Footprint |

| Dimensions | L: 4.13” W: 1.00” H: 4.13” |

| Weight | 5.9 oz |

| Construction (wetted materials): | |

| Manifold | Nickel Plated Aluminum |

| O-Rings | Fluorocarbon (Viton®), others at additional cost |

| Flow Sensor | Ceramic Flow Tube (non-out gassing), Silicon, Silicon Nitrite Gold, Aluminum Oxide Epoxy Sealant, Fluorocarbon (Viton®), Polythermide (100, 200 & 300 sccm MFC only) |

Why Accurate Mass Flow Measurement Matters

Gas flow control is not simply about moving molecules from one point to another. It is about ensuring process consistency, maintaining quality, and safeguarding sensitive operations.

- In analytical instrumentation, precise flow of carrier or calibration gases ensures reproducible results.

- In thin-film deposition or semiconductor processes, uniform gas delivery is critical for product quality and yield.

- In vacuum-based and automated systems, reliable mass flow measurement supports process stability and reduces downtime.

Thermal mass flow technology, used in the ManiMeter, measures mass flow independent of temperature and pressure variations, providing consistent, reliable readings even under challenging conditions. This makes it a preferred choice for demanding applications where volumetric measurement methods fall short.

The ManiMeter Difference

The ManiMeter was engineered to address three key challenges: space, integration, and performance.

- Compact Manifold-Mount Design: Fits directly into manifold systems, reducing tubing, fittings, and potential leak points while conserving valuable rack or panel space.

- Exceptional Accuracy & Stability: Maintains consistent flow with minimal linearity errors, giving engineers confidence in long-term reliability.

- Digital Connectivity: Supports analog and digital outputs (VDC, mA, RS-232), allowing seamless integration into modern data acquisition and control systems.

- Durable Construction: High-quality materials like nickel-plated aluminum and Viton® seals provide long-lasting performance in demanding environments.

By combining these elements, the ManiMeter ensures high-precision mass flow control in a space-efficient, easily integrable package.

Integration with Manifold Systems

Manifold mount gas delivery systems are increasingly popular for their compactness, efficiency, and reduced leakage.

The ManiMeter is optimized for manifold integration, allowing:

- Multiple meters to be installed side-by-side without complex tubing or fittings.

- Reduced installation costs and faster system response.

- Streamlined OEM integration, enabling faster product development without design compromises.

This integration ensures that engineers can scale operations smoothly while maintaining the accuracy and repeatability required for advanced applications.

Applications of ManiMeter Mass Flow Meters

- Analytical Instrumentation: Precise carrier and calibration gas delivery ensures reliable and repeatable results for laboratories and research facilities.

- Semiconductor & Vacuum Coating: Maintains uniform gas flow in thin-film deposition and plasma coating processes, ensuring consistent product quality.

- Industrial Automation: Enables digital control and real-time monitoring, supporting automation systems that demand high reliability and repeatability.

- Environmental & Energy Research: Provides accurate gas usage data for process optimization, resource efficiency, and sustainable operations.

The ManiMeter delivers precision, reliability, and integration flexibility, making it ideal for industries where every millisecond and molecule counts.

Why Engineers Choose ManiMeter™

Engineers rely on the ManiMeter not only for what it measures but also for how it simplifies gas flow system design:

- Compact & Efficient: Reduces space, tubing, and installation complexity.

- Reliable & Accurate: Minimizes recalibration and ensures long-term process stability.

- Digital-Ready: Integrates easily into modern automated and data-driven systems.

By addressing common challenges in gas flow control, the ManiMeter allows engineers to focus on innovation, process optimization, and cost reduction.