[vc_row][vc_column width=”1/6″ el_class=”products-sidebar mb-5″ css=”.vc_custom_1737013963589{padding-top: 20px !important;padding-right: 30px !important;padding-bottom: 20px !important;padding-left: 30px !important;}”][vc_widget_sidebar sidebar_id=”product-widgets” el_class=”mb-0″][/vc_column][vc_column width=”2/3″ el_class=”py-0″][vc_row_inner css=”.vc_custom_1737013930403{margin-bottom: 50px !important;}” el_class=”row”][vc_column_inner el_class=”inner-products-box px-3 mb-4″ width=”1/4″ css=”.vc_custom_1734590759362{padding-top: 20px !important;padding-right: 20px !important;padding-bottom: 20px !important;padding-left: 20px !important;border-color: #000000 !important;}”][vc_column_text css=”.vc_custom_1748599676018{margin-bottom: 0px !important;}”]

ManiMeter

L: 2.00” W: 1.50” H: 2.00”

Learn More [1]

[/vc_column_text][/vc_column_inner][vc_column_inner el_class=”inner-products-box px-3 mb-4″ width=”1/4″ css=”.vc_custom_1734590772209{margin-bottom: 30px !important;padding-top: 20px !important;padding-bottom: 20px !important;}”][vc_column_text css=”.vc_custom_1748599668603{margin-bottom: 0px !important;}”]

MicroMeter

L: 2.04″ W: 1.50″ H: 1.87″

Learn More [2][/vc_column_text][/vc_column_inner][vc_column_inner el_class=”inner-products-box px-3 mb-4″ width=”1/4″ css=”.vc_custom_1734590781585{margin-bottom: 30px !important;padding-top: 20px !important;padding-bottom: 20px !important;}”][vc_column_text css=”.vc_custom_1748599815867{margin-bottom: 0px !important;}”]

MediMeter

L: 2.8″ W: 1.50″ H: 5.63″

Learn More [3][/vc_column_text][/vc_column_inner][vc_column_inner el_class=”inner-products-box px-3 mb-4″ width=”1/4″][vc_column_text css=”.vc_custom_1748599828899{margin-bottom: 0px !important;}”]

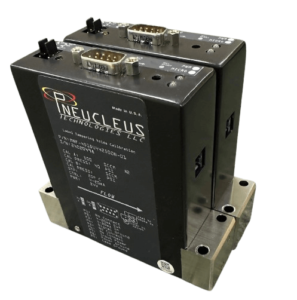

MetaMeter

L: 5.5″ W: 1.50″ H: 2.8″

Learn More [4][/vc_column_text][/vc_column_inner][/vc_row_inner][vc_column_text css=””]

| Digital Models | ||||

| Flow Range | Up to 2000sccm | Up to 20 SLPM | Up to 20 SLPM | |

| Linearity Error: | 0.5% FS | 0.5% FS | 0.5% or 1.0% FS* | |

| Repeatability | 0.15% FS | 0.15% FS | 0.15% FS | |

| Response Time | 40ms | 150ms | 100ms | |

[/vc_column_text][/vc_column][vc_column width=”1/6″][/vc_column][vc_column][vc_row_inner][vc_column_inner css=”.vc_custom_1749567430137{padding-right: 36px !important;padding-left: 36px !important;}”][vc_column_text css=””]Mass flow meters are widely used instruments to measure the mass flow rate of gases or liquids, offering accurate flow control critical for industrial processes. Unlike volumetric meters, they determine the actual mass of the medium regardless of variations in pressure or temperature, ensuring consistent and reliable measurements. Industries such as oil & gas, pharmaceuticals, food processing, and chemical manufacturing depend on mass flow meters to enhance efficiency, maintain safety, and optimize resource usage.

At Pneucleus Technologies LLC, we provide reliable mass flow meters for gases that deliver high-precision results. These devices are ideal for monitoring and optimizing flow processes across industrial sectors. Their advanced design ensures durability, low maintenance, and superior performance.[/vc_column_text][vc_column_text css=””]

How Do Mass Flow Meters Work with Gases?

Pneucleus Mass flow Meters are based on the heat transfer from a hot wire centered between two resistive thermal detectors (RTD’s), one upstream RTD and one downstream of the hot wire. This is called a hot-wire anemometer. At zero flow the heat plume from the hot wire heats both RTD’s equally causing the resistance of each RTD to be the same. A precisely regulated voltage is applied to two legs of a bridge circuit where at the top of each leg is a laser trimmed pull-up resistor that connects to either the upstream RTD or the downstream RTD. The current through each leg creates a voltage drop that is equal and balanced across each RTD at zero-flow. When gas begins to flow, the upstream RTD is cooled which decreases its resistance and therefore its voltage drop. The downstream RTD temperature increases as the heat plume begins to lean toward it. It’s resistance increases resulting is a larger voltage drop.

The difference between the upstream voltage and the downstream voltage is proportional to the flow rate across the anemometer. These variations are dependent on the mass, thermal conductivity and the velocity of the gas that is flowing through the anemometer. By measuring the gas flow with a precisely calibrated flow standard that is calibrated for the gas type under test, the anemometer voltage differential can be precisely calibrated to output a voltage correlating to the mass flow rate measured by the precision flow standard. The hot-wire is regulated to maintain a temperature 160 degrees above ambient. This is how mass flow can be measured with little concern about the ambient temperature or pressure.

This precision makes mass flow meters ideal for applications requiring exact quantification of flow in both industrial and laboratory settings.

Types of Mass Flow Meters Offered by the Pneucleus Technologies

Pneucleus Technologies is one of the most trusted and reliable providers of precision mass flow meters, engineered to deliver superior accuracy and efficiency for gas flow measurement applications. We offer 4 main types of products – ManiMeter, MicroMeter, MediMeter, and MetaMeter Mass Flow Meters. Each are tailored to measure any customer specified flow range and/or performance requirements while offering different geometries to fit into any application.

- ManiMeter [1]: Manifold-mount design with flow up to 6000 SCCM, ±0.5% linearity, ±0.08% repeatability, and 20ms response. Compact Manifold-Mount for reliable easily maintained integrated gas distribution systems.

- MicroMeter [2]: A Subminiaturized meter for low flows up to 6000 SCCM, and performance up to ±0.5% linearity, ±0.08% repeatability, and 20ms response. Perfect for precise lab, vacuum coating, analytical instrumentation and other applications where space is at a premium.

- MediMeter [3]: Traditional design for flows up to 20,000 SCCM, and performance up to ±0.5% linearity, ±0.08% repeatability, and 20ms response. Ideal for process control and industrial uses.

- MetaMeter [4]: Low-profile meter supporting up to 20,000 SCCM, and performance up to ±0.5% linearity, ±0.15% repeatability, and 20ms response. Durable and reliable for demanding medical and research environments.

Application of Mass Flow Meters

Our digital gas mass flow meters offer easy and precise flow measurement across industrial processes. Also, with advanced features such as direct sensing technology, these thermal mass meters can instantly respond to even minute changes in flow. Here are some of their application areas.

- Oil & Gas: Used for gas flow monitoring and controlling fuel flow in combustion systems.

- Pharmaceutical: Ensures accurate gas flow measurement during production processes to maintain quality and compliance.

- Environmental Monitoring: Used for emission monitoring and controlling gas flow in pollution control systems.

- Food & Beverage: Supports gas flow control in carbonation, fermentation, and packaging processes.

- Chemical: Facilitates safe and accurate measurement of gases and liquids in various chemical reactions.

- HVAC Systems: Thermal mass flow meters are used for air flow measurement in heating, ventilation, and air conditioning systems.

- Semiconductor Manufacturing: Digital gas mass flow meters ensure precise delivery of specialty gases during chip fabrication.

Tips to Choose the Right Mass Flow Meter

Choosing the right mass flow meter is crucial for ensuring precise measurements and optimal system performance. Here are key tips to guide your decision.

- Understand Your Application Requirement: Determine the gas types to be used, flow ranges, and operating conditions including ambient temperature and applied gas pressures, both up and downstream. This will affect how the mass flow meter (MFM) is calibrated.

- Price, Accuracy & Repeatability: Select a meter that offers the speed and accuracy that your application requires at a price that maximizes profitability.

- Pressure and Temperature Compatibility: Ensure the meter is calibrated for and can withstand your system’s temperature and pressure ranges.

- Material Compatibility: Verify the meter’s materials compatibility in terms of the gas-types being measured.

- Ease of Installation and Maintenance: Choose a user-friendly design that simplifies operation and maintenance.

Want to optimize your gas flow measurement? Pneucleus Technologies offers reliable, high-performance mass flow meters. Designed for accuracy and efficiency, our solutions meet your operational needs. Have a requirement or query? Contact our sales engineers today and ensure you get the precision and performance your application deserve at the lowest cost in the industry.

FAQs

What are the key advantages of using a mass flow meter over a volumetric flow meter?

Mass flow meters offer higher accuracy because they are unaffected by temperature and pressure variations, making them ideal for precise fluid measurements in industrial processes.

Can mass flow meters measure low flow rates?

Yes, mass flow meters, especially thermal types, are highly effective for low flow rate measurements with great sensitivity.

How do temperature and pressure impact thermal mass flow meters?

Thermal meters rely on heat transfer, so temperature and pressure changes can influence the accuracy if not calibrated correctly using precise & traceable Mass Flow Standards.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][vc_column][/vc_column][vc_column][/vc_column][vc_column][/vc_column][/vc_row]